May 13, 2020

How to Confidently Choose the Right Mic

By Ron Streicher

Introduction

Ask any group of engineers about how they choose the right microphone for a given situation, and you will get at least as many answers as the people you talk to. Microphone selection is the ‘black art’ of the recording process and although everyone does it, few can explain adequately how or why they do what they do. On the other hand, much has been written about how to choose the right microphone. In fact, this might even be the most frequent topic to appear in the numerous trade publications of the audio industry. Entire books, and even college courses, address this issue – and with good reason: proper microphone selection is undeniably the most critical aspect in the making of any recording.

In this brief introduction to Micpedia, our goal is to provide you with an overview of the basic concepts of how microphones respond to sound, their polar patterns, powering schemes, and some of the pragmatic issues relating to microphone usage and placement.

With this fundamental knowledge, you will have a better understanding of the technical data presented in this book and how to interpret it to help you to decide which microphones will best suit your particular needs. Because a comprehensive treatment of microphone technology is not within the scope of this text, several recommended reference books are listed in the Bibliography.

We must emphasise, however, that intimate knowledge of how microphones actually perform is not a trivial matter. No article or book truly can tell you how to choose or use a microphone; this comes only with practical hands-on and ears-on experience. What they can do, however, is provide you with the information that will help you narrow down the possibilities.

Microphones as transducers

All microphones are designed to convert one form of energy (acoustical) into another (electrical). The term for such a device is a transducer. Although there are several mechanisms available for accomplishing this task, for professional recording applications, we can limit our attention to two basic categories of microphone transducers: dynamic and condenser. (The ‘condenser’ microphone is also called a ‘capacitor’ microphone in parts of Europe.) Within each of these two categories, are two sub-categories: dynamic microphone transducers can be comprised of either a ‘moving coil’ or a ‘ribbon’ motor-generator; condenser transducers can be either externally polarised (a true capacitor element) or permanently polarised, known commonly as an electret element.

A second important distinction can also be made among microphones, whether dynamic or condenser, and that is how they respond to the sound waves as they arrive at the transducer’s diaphragm. The first type is known as a pressure transducer (more properly, ‘pressure responding transducer) and reacts only to variations in the absolute pressure of air – the compressions and rarefactions – created by the soundwave; these microphones are always omnidirectional. The second type is known as a pressure-gradient transducer (sometimes called a velocity microphone), and reacts in proportion to the differences in the air pressure on either side of the diaphragm; these always have a directional polar response pattern.

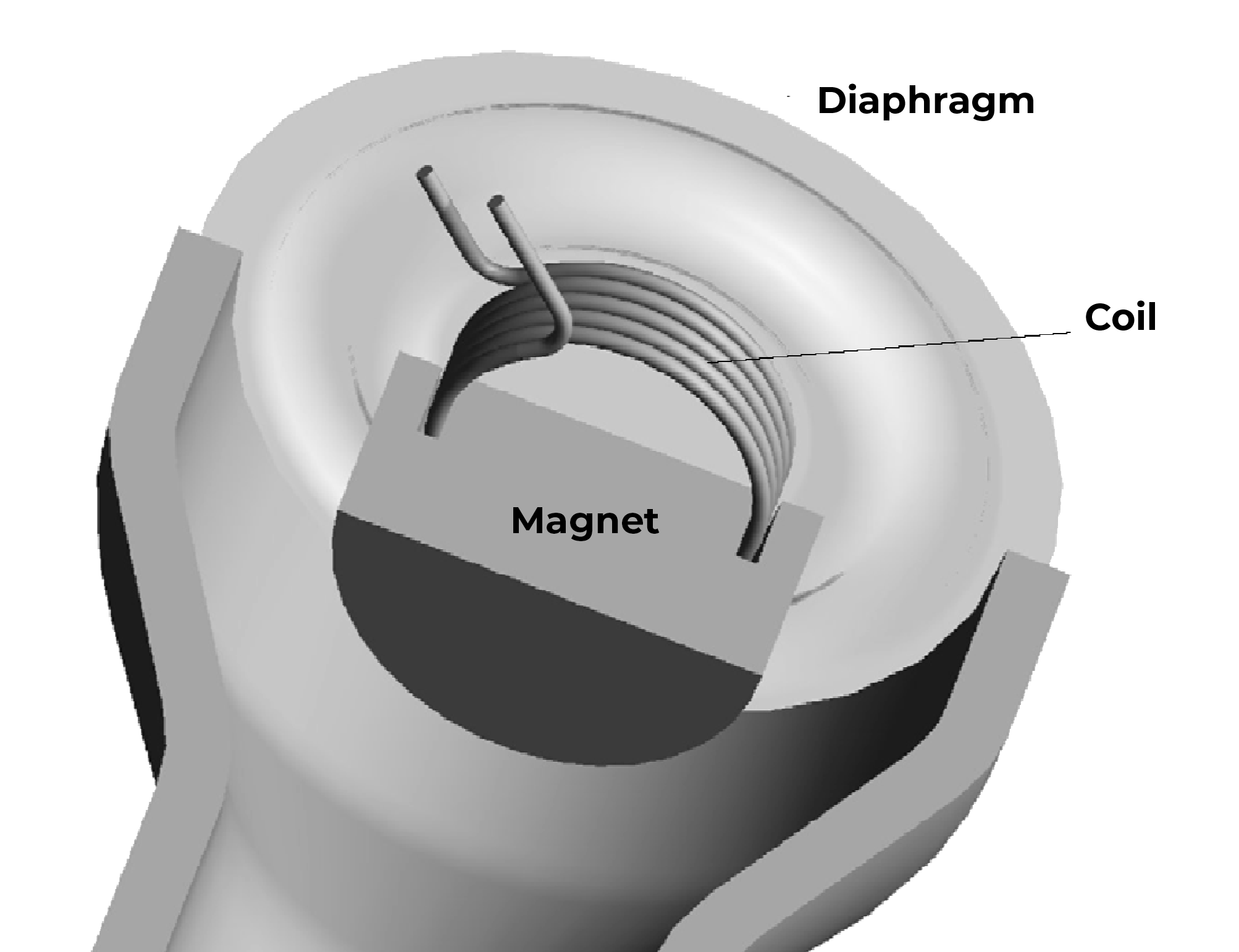

Moving-coil transducers

The moving-coil transducer is, perhaps, the most widely used type of microphone in professional audio – particularly by the sound reinforcement industry. It is simple and rugged in design, relatively inexpensive to manufacture, and can be very effective throughout most of the audio frequency bandwidth.

In its simplest form, the diaphragm is a tightly stretched membrane (usually of very thin plastic) with a thin coil of wire glued to the back; the coil of wire is surrounded by a permanent magnet. When the acoustical energy from a soundwave causes the diaphragm to move, this in turn moves the coil within the magnetic field, generating a small electrical current. (In essence, this operates like a loudspeaker in reverse.) Because the current generated is proportional to the energy of the soundwave, it is an electrical analogue of the acoustical signal. This principle is common to all microphone types and is the basis of how microphones work as transducers. Moving-coil microphones can be either pressure or pressure-gradient types, depending on how they are constructed. (These differences will be discussed later in this article.) While moving-coil microphones can exhibit extremely broad frequency response, their ability to move very rapidly, i.e., their transient response, is limited due to the mass of the diaphragm and coil.

Ribbon transducers

Employing a similar ‘motor-generator’ principle, the ribbon microphone’s diaphragm is a very thin metallic ribbon (usually aluminium) suspended between the poles of a very strong magnet. As described above, when the acoustical energy from the soundwave causes the ribbon to move within the magnetic field, an electrical current is generated. However, because the ribbon has considerably less mass than the moving-coil diaphragm (the ribbon in the classic RCA 44, for example, is only 1.8 microns thick), it is able to respond much more rapidly to the changes in air pressure, and therefore exhibits an exceptionally good transient response. This thinness, however, also makes ribbon microphones more fragile and susceptible to damage from strong air turbulence such as wind, breath blasts, or extremely high Sound Pressure Levels (SPL) at very low frequencies.

Because of their inherent design, ribbon microphones are always pressure-gradient transducers, and therefore are directional in nature. Most commonly, they have a bidirectional polar pattern, although there are some that are designed to be more unidirectional. As described, both moving-coil and ribbon microphones directly generate a very small electrical current. A ‘step-up’ transformer is included within the microphone to increase this current to a level sufficient to travel down the cable to the next element in the audio system. Even so, they will have a relatively low electrical output sensitivity. Their ability to withstand rather high SPL before going into distortion, however, is a distinct advantage of their design.

Condenser transducers

In a condenser microphone, the diaphragm itself is one pole of a capacitor within an electrical circuit. As the acoustical energy stimulates the diaphragm into motion, its distance relative to the other pole changes, thus varying the capacitance in the circuit. These variations, as with the dynamic microphone, create an electrical analogue of the original acoustical signal.

As mentioned earlier, the capacitor element may be charged by an external source of power, or it may bear a permanent charge. The latter is known as an electret condenser. In either case, a preamplifier circuit is contained within the microphone body to increase signal level; this amplifier may derive its power either from an external supply or, in the case of the electret mic, from an internal battery. It is this amplifier circuit that is often the limiting factor for the SPL rating of a condenser microphone, as the preamplifier can be driven into overload from a high SPL signal and result in distortion within the microphone. While it is possible for the diaphragm to move far enough actually to come into contact with the back plate (this is known as ‘bottoming-out’ and results in a loud snap or crack as an electrical arc develops between the two poles of the capacitor) this is not all that common; more often, it is the preamplifier going into overload from a high SPL signal that results in distortion from the microphone. As a protection, a pad is often built into the microphone; this reduces the signal level from the capsule into the preamplifier, thus extending the higher SPL range of the microphone. Users should note that external pads, or those built into mixing consoles, cannot prevent or cure overload distortion that occurs within the microphone itself.

Another aspect of this internal preamplifier is the self-noise factor of the condenser microphone. This is a measure of the noise generated by the preamplifier itself, and the lower the specified value, the better the microphone will perform. Because the diaphragm element of a condenser microphone can be made of very thin material (and is not encumbered by a coil glued to its backside), it can respond very quickly to variations in air pressure and therefore exhibit excellent transient response.

Condenser microphones can be either pressure or pressure-gradient transducers. Some ‘modular’ condenser microphone systems offer interchangeable capsules that go onto a common preamplifier module; in this way, a variety of individual polar patterns can be achieved with a single microphone. Because of their electrical design, condenser microphones that offer multiple polar patterns can also be created. This is achieved by placing two condenser diaphragms back-to-back in one element and combining their electrical outputs with an addition/subtraction network. Their versatility can make these some of the most versatile microphones in your kit.

Polar response patterns

Microphones also can be divided into two groups with respect to their polar response pattern: non-directional (or omnidirectional) and directional. As the name implies, non-directional microphones (“omnis“) respond equally to sound arriving from any and all directions – at least, this is the ideal. This is because they respond only to variations in absolute pressure, irrespective of the direction of the source. In actuality, however, even the best omnidirectional microphones tend to become directional at higher frequencies as a result of the laws of physics: the shorter wavelengths of high frequencies become ‘shadowed’ by the size of the microphone body itself and are therefore reduced in amplitude before they reach the diaphragm. There also are a variety of other mitigating factors relating to the wavelength of the sound compared to the size of the diaphragm, but these are beyond the scope of this article. For more information see Bibliography.

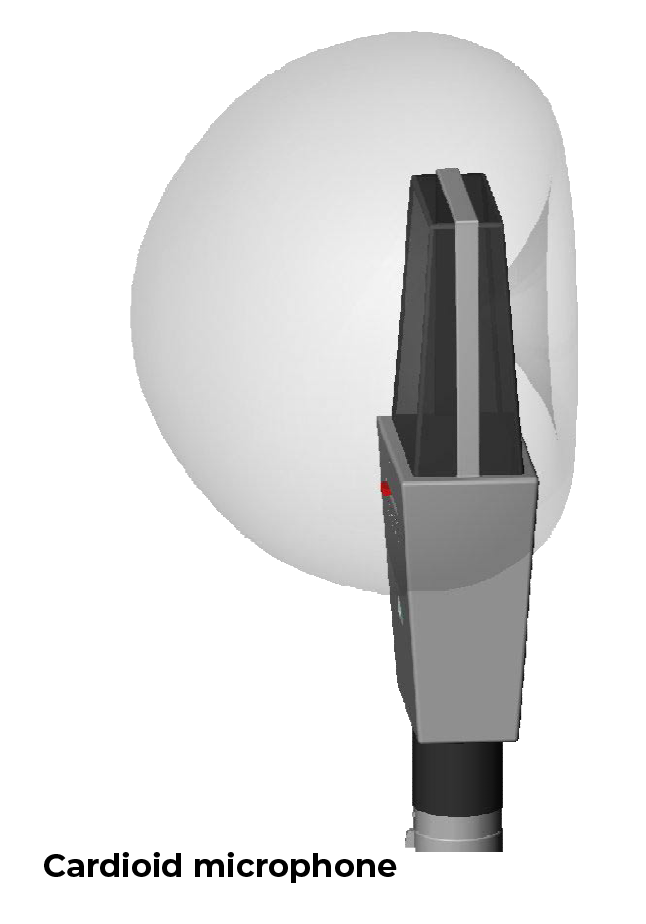

The term ‘directional microphone’ encompasses a wide variety of polar response patterns. The most commonly used directional microphone is the cardioid, whose name implies a ‘heart-shaped’ pattern. However, this is really not very accurate, for the cardioid pattern is not pointed at the front as would be a traditional Valentine heart; neither does it at all resemble the shape of a real heart. Rather, it might be preferable to describe this pattern as being more like the shape of a cherry, where the point that the stem attaches to the fruit is the microphone diaphragm and the fruit itself is the polar response. The term unidirectional is also used (albeit somewhat incorrectly) to describe cardioid microphones.

It is important to remember that all polar response patterns should be considered as being three-dimensional – a factor often overlooked by many microphone designs whose response might be very good in the horizontal plane, but very ragged in the vertical.

Cardioid microphone

A proper cardioid microphone pattern has a smoothly declining response as the sound source moves away from the principal axis of pickup; when the sound source is at ±90° the level is reduced by -6dB. The response continues to decline until it reaches a ‘null’ at 180°. With a well-designed cardioid microphone, the frequency response will be fairly consistent with the polar pattern until you reach the rear of the microphone, where the lower frequencies will still remain while the mid and high frequencies will be significantly reduced. Again, this is due to the laws of physics as they relate to the wavelengths of the sound and how they cancel between the front and rear entries to the diaphragm.

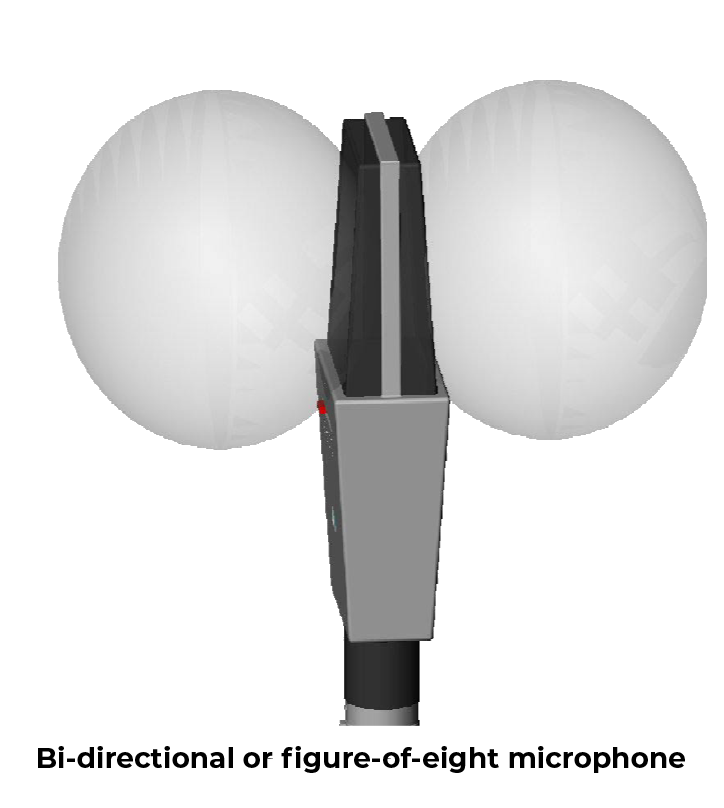

Figure-of-eight microphone

Another common directional pattern is the bi-directional or figure-of-eight microphone. If an omnidirectional microphone pattern can be thought of as a ‘beachball,’ a bi-directional microphone could be viewed as two beachballs glued together. There are two lobes of primary response, one to the front of the diaphragm and the other to the rear; they are of equal sensitivity, but of opposite polarity. This means that a positive-going pressure wave approaching the front of the microphone will result in a positive voltage at the output, and a negative voltage if it approaches from the rear. There is a very deep null at ±90° which, with a well-designed single-diaphragm microphone, can approach -90dB at all frequencies. This is because a truly bi-directional microphone is a pressure-gradient mic as described above, and at ±90° there will be no difference in the pressure on the two sides of the diaphragm, so there will be essentially no output. The classic ribbon microphones produced by RCA in the 1930s and 1940s set the standards for this polar pattern even today.

Modern multi-pattern condenser microphones can also produce bi-directional patterns, but because there is a small gap between the two diaphragms of the condenser capsule, the 90° null will not be as deep as with a single-diaphragm condenser or ribbon microphone. Also, at very high frequencies, the short wavelengths relative to the diaphragm spacing can also result in an erratic off-axis polar response.

Among other first-order directional patterns, the most common are the supercardioid and the hypercardioid. These two patterns are similar in that they have a dominant frontal lobe that is considerably narrower than that of a bi-directional mic and a small rear lobe. There are two nulls associated with these patterns, and their positions generally range between ±120°and ±150°.

Another, somewhat less directional pattern, is subcardioid. This can be visualised as a beachball pressed against a wall: it has a broad frontal pickup and only a slightly reduced sensitivity to the rear, with no actual null. It is also called a ‘wide cardioid.’

Finally, the most narrow directional pattern is attributed to the ‘shotgun’ microphone. However, this is a bit of a misnomer, because the actual polar pattern can be rather broad on-axis, and it is plagued with numerous and erratic lobes off-axis. Properly called an interference-tube microphone, its narrow frontal pickup is the result of variable and multiple phase cancellations as the soundwave approaches the diaphragm along the length of the tube. This is achieved, however, at the expense of serious off-axis colourations.

Proximity effect and other frequency anomalies

It must be noted that all directional (i.e., pressure gradient) microphones exhibit some degree of proximity effect. The British call this ‘bass tip-up’, a term that quite accurately describes the results of this phenomenon: an artificial boosting of the low-frequency response of the microphone as it is placed close to the source of the sound. Although most microphone data sheets show the effects of this boost only at very short distances (usually less than 45cm) it is known that with some microphones, proximity effect actually can be detected at distances as far as 90cm.

Sometimes this effect can be used as an artistic benefit; for example, with male singers, it can ‘fatten’ their sound and make them seem ‘more masculine.’ It also tends to overcome the natural roll-off of the very low frequencies that is inherent with all directional microphones. With musical instruments, however, proximity effect more often serves only to ‘muddy’ the sound and make the instrument sound thick and heavy. With speech, it can also cause a significant loss in articulation.

Closely associated with proximity effect is the susceptibility of directional microphones to low-frequency distortions caused by excessive breath or wind turbulence. This factor is the cause of the infamous ‘popping’ and low-frequency rumble all too often heard when these microphones are used without adequate windscreens. Compounding this situation is the reduced high-frequency response caused by these protective devices.

Omnidirectional pressure microphones, on the other hand, are less susceptible to these problems. Multi-pattern microphones, however, do exhibit some proximity effect and wind/breath problems even when set to their omnidirectional position. This is because they achieve the omni pattern by summing two essentially cardioid diaphragms.

Microphone powering systems

In the preceding discussion of condenser microphones, it was mentioned that the amplifiers of these mics require power from either an internal battery or an external supply. Electret condenser mics often include an internal battery, and this can be sufficient to operate the mic for several hours or even days. ‘True’ condenser mics, however, almost always require an external power system.

Setting aside tube microphones for the moment, almost all true condenser and many electret condenser microphones are powered by what is commonly called Phantom Power; another term for this is simplex power. In this system, a voltage (typically +48 VDC) is applied equally to Pins 2 and 3, relative to Ground (Pin-1). Note that there is no DC voltage differential between Pins 2 and 3, which carry the audio signal; this is why this is called ‘phantom’ power. This voltage is used within the microphone to polarise the capsule (if necessary) and power the internal amplifier circuitry.

Another powering system, although now found primarily in older equipment intended for use by the motion-picture industry, is called AB or T-Power. In this scheme, +12 VDC is applied to Pin-2 relative to Pin-3 (or vice versa); Pin-1 is still Ground and has no bearing on the powering of the microphone. In this situation, there is a 12-Volt DC differential between Pins 2 and 3, and this induces a DC offset into the audio signal also on these pins.

Phantom and/or AB powering is commonly provided by most mixing consoles as well as portable recording devices. It can also be provided by dedicated in-line power supplies.

It is important to know which form of power a microphone requires. Connecting the wrong power to a microphone can cause serious damage to the microphone, the power supply, or both. It is also very important to remember that no ribbon microphone should ever be connected to a phantom or AB-powered circuit. Immediate damage to the microphone is the likely result.

Tube condenser microphones, and some others as well, require individual dedicated power supplies (PSUs); these are most often connected to the microphones via special multi-conductor cables and connectors. Separate voltages are provided to polarise the capsule and to operate the electronics within the microphone. Because each microphone requires its own special supply, these are generally not interchangeable from one microphone to another.

Choosing a microphone

The first step in choosing the right microphone for any particular application is to understand the sonic nature of the subject: factors such as the frequency range, transient and spectral characteristics, and dynamic range need to be considered. However, it does not end here; the environment in which the subject is situated and the effects this will have on the desired sound pickup also need to be given proper attention. Thus, the right microphone must be able not only to ‘capture’ the true sonic character of the subject accurately, it must also be able to accept or reject the desirable or unwanted sounds respectively coming from the environment surrounding that subject.

Accurate sonic replication of the sound source is, of course, a very subjective matter. There are instances where the particular sonic characteristics of a microphone are purposely employed to alter the sound of the subject in a desired manner. This can be an essential element of the ‘creative’ process of recording.

A key element in this selection, therefore, is the polar pattern of the microphone pickup. In a ‘perfect world,’ all microphones could be omnidirectional because this would ensure uncompromised bandwidth and perfect off-axis pickup with minimal coloration. They would also be condenser transducers to provide excellent transient response, sensitivity, and dynamic range. Sadly, however, we rarely have the privilege of working in a perfect world.

Sometimes we simply need a microphone that is more rugged and robust than a condenser and must therefore use a moving-coil microphone, with its resulting compromise of the transient response and bandwidth. At other times a directional microphone will be necessary, such as when dealing with poor acoustics or sound reinforcement applications. In these situations, we are forced to accept its off-axis coloration, reduced low-frequency response, proximity effect, and susceptibility to wind and breath noise. These are facts of life dictated by the laws of physics and circumstance.

Knowing the limitations inherent in each of the microphones in your equipment locker will help you to choose the set that will result in the least compromises to your project.

Proper placement of the microphone is equally, if not even more, significant. With directional microphones, it is often more beneficial to ‘aim the nulls’ than the principal axis of the microphone. This is why a directional microphone is chosen – because of its ability to offer some rejection of unwanted sounds. If rejection is not an issue, the omnidirectional microphone is always a better choice because of its superior overall response characteristics. However, one other factor should be considered before making the decision to use a directional microphone: the Distance Factor. There is a simplified rule, known as the Two-to-One Rule, which states that an omnidirectional microphone positioned at half the distance of a cardioid will provide the same direct-to-reverberant sound ratio. Thus, if you have been using a cardioid mic to reduce feedback or the ‘leakage’ of sound from one instrument into the mic of another, for example, you could use an omni at half the distance to achieve the same effect and, at the same time, gain a better off-axis response and eliminate the proximity effect inherent in the cardioid.

The application for which the microphone is used also plays an important role. Microphones used for sound reinforcement generally need to be more robust than those used for studio recording applications. Thus, their sensitivity is often sacrificed in favour of the ability to withstand the rigours of hand-held use or high SPL environments. Similarly, microphones used outdoors must also be better able to withstand the hostility of an open environment than the very delicate tube or condenser microphones found in the recording studio. These factors also need to be considered when choosing a microphone for a particular project. Selecting microphones to comprise stereo pairs also requires close matching of the characteristics of the mics: polar pattern and off-axis response should match very closely so that the stereo image does not ‘wander’ or experience unnatural colorations as the subject moves up and down within its frequency range. This is particularly important with all directional microphones because most stereo configurations require that the majority of the sound is picked up off of the principal axis of the microphone. For more information, see Bibliography.

The art of compromise

The art of making a good recording is based largely on the ‘art of compromise.’ Everything you do affects everything else in the process. Sometimes the compromises can be minimal; at other times, they can come right up and hit you in the face! Technical factors, environmental concerns, visual considerations, and economic limitations – all play their roles in determining the selection of microphones (or other equipment in the audio chain) and hence the final outcome of the project. It is the role of the engineer and producer to balance carefully these varying, and often opposing, considerations and choose the right set of compromises to complete the project with the maximum of success.

We hope that Micpedia will help you to make an enlightened decision and therefore minimise your compromises – at least with regard to your selection and use of microphones. Good luck!

Ron Streicher is an audio production engineer with a long history of classical recordings to his name. Based in Los Angeles, he is a fellow of the AES and is a renowned author of microphone and recording technique books.

First published in Microphone Data Book 2001

© 2022 ODRATEK BV